Featured

Yield Point In Stress Strain Curve

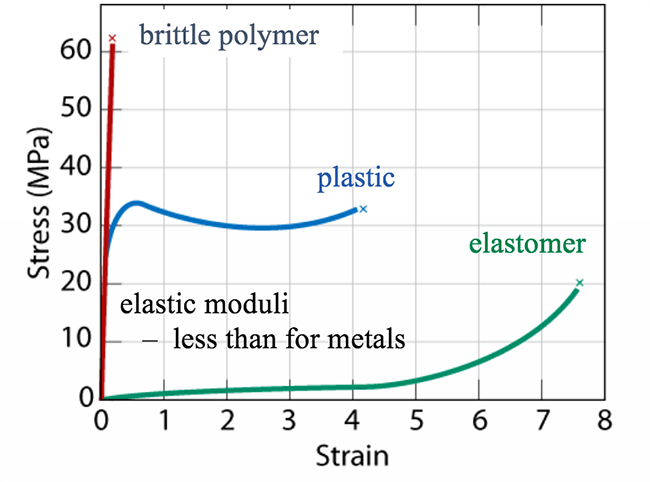

Yield Point In Stress Strain Curve. Elastic point & yield point. The yield point is defined as the point at which the material starts to deform plastically.

Yield strength or yield stress is the material property defined as the stress at which a material begins to deform plastically whereas yield point is the point where nonlinear (elastic + plastic) deformation begins. The portion of the curve between \(b\) and \(d\) shows, if the load is increased further, the stress developed exceeds the yield strength, and strain increases rapidly even for a small. Because engineering stress is proportional to the force applied along the sample, the criterion for necking formation can be set as δ f = 0 {\displaystyle \delta f=0}.

Beyond Point D Higher Stress Is Required For Higher Strain, Than Those Between Proportional Limit A And Yield Point D.

Do we have to use the 0.2% offset method to calculate the. Yield point meaning in structural engineering is the load at which a solid material that is stretched begins to flow or change shape permanently. For metals, yield is generally calculated at 2% offset.

Normally We Use The Lower Yield Point To Determine The Yield Strength Of The Material Being Tested, Cause The Uppe.

It is a point that represents the maximum stress that a material can endure before failure. Stress strain curve is defined as the curve or a graphical representation of a material’s stress and its strain and understood the relationship between stress and strain. Once the yield point is passed, some fraction of the deformation will be permanent.

Before The Yield Point, A Material Bends By Stretching Atomic Bonds.

(v) fracture or breaking point: Yield strength refers to an indication of maximum stress that can be developed in a material without causing plastic deformation. When the applied axial load the deformation is took place into the testing object but if load is removed from the yield point of testing object then the testing object can go back to its.

Yield Strength Or Yield Stress Is The Material Property Defined As The Stress At Which A Material Begins To Deform Plastically Whereas Yield Point Is The Point Where Nonlinear (Elastic + Plastic) Deformation Begins.

It is obtained by gradually applying load to a test coupon and measuring the deformation, from which the stress and. In the stress strain curve the yield point particularly indicate the point where elasticity ended and plasticity is begins. Beyond the yield point, the atoms have stretched to their limit and further deformation happens because atoms move past each other.

1 Does Not Exhibit A Sharp Yield Point, But Rather A Gradual Decrease In Modulus Of Elasticity.

Checkout jee mains 2022 question paper analysis : Stress strain curve graph basic. What is yield point in stress strain curve?

Popular Posts

How To Make A Curved Arrow In Photoshop

- Get link

- X

- Other Apps

Comments

Post a Comment